How Do Industry Standards Impact Circuit Board Assembly Practices?

Industry Standards Impact Circuit Board Assembly Practices

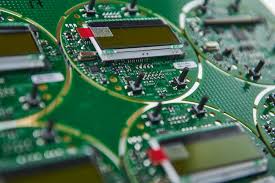

The quality of printed circuit boards is critical to the performance and reliability of electronic devices and systems. A jiggling component or a loose screw can significantly impact the functionality of a product, so it’s crucial to follow established industry standards to ensure the smooth operation of these complex pieces of hardware. Non-compliance with these standards can lead to a variety of problems, including potential safety hazards and legal ramifications. However, by aligning with these standards and adhering to rigorous testing and inspection practices, manufacturers can produce high-quality, reliable products for their customers.

A key element of circuit board assembly is the use of solder paste. This substance is used to adhere surface mount components to the PCB and hold them in place until they are soldered by a skilled technician. The quality of this paste is vital because it determines how well the components will adhere to the board and how secure they will be once they are in place. A poor-quality paste will allow the components to move, detach, or even melt, resulting in a defective end product.

Fortunately, modern technology has brought a host of new solutions to the assembly process, helping to streamline and enhance both efficiency and quality. For example, the use of automated pick-and-place machines allows for quick and precise placement of components on a board, reducing the margin of error during at-scale production. In addition, advanced reflow soldering techniques provide greater control over temperature profiles and the formation of solder joints, further increasing reliability and consistency.

How Do Industry Standards Impact Circuit Board Assembly Practices?

In addition to utilizing the latest technology, manufacturers should work with a PCB manufacturer that employs local employees and uses American-made equipment. This helps support the local economy and contributes to the development of future electronics technologies. This forward-thinking approach can help businesses stay ahead of the curve and continue to meet consumer demand for innovative, cutting-edge technology.

Another important factor in ensuring successful circuit board assembly is establishing and implementing a robust quality control system. This includes the use of Pareto charts to prioritize issues based on their frequency and severity, and leveraging tools like process optimization to reduce inefficiencies and prevent defects. Furthermore, implementing training and skill development programs helps staff members become more adept at detecting issues and identifying the root causes of those issues.

While it is possible to assemble circuit boards in-house, the cost and time commitment may be prohibitive for some businesses. It’s often more cost-effective and efficient to partner with an experienced, professional PCB manufacturer for all of your electronics manufacturing needs. They will have the expertise and equipment necessary to produce a high-quality, functional product that will help your company thrive in today’s fast-paced business landscape. Choosing the right partner will also give you peace of mind that your final product will perform as intended, allowing you to focus on your core business.